Why Towbar Quality Matters More Than You Think

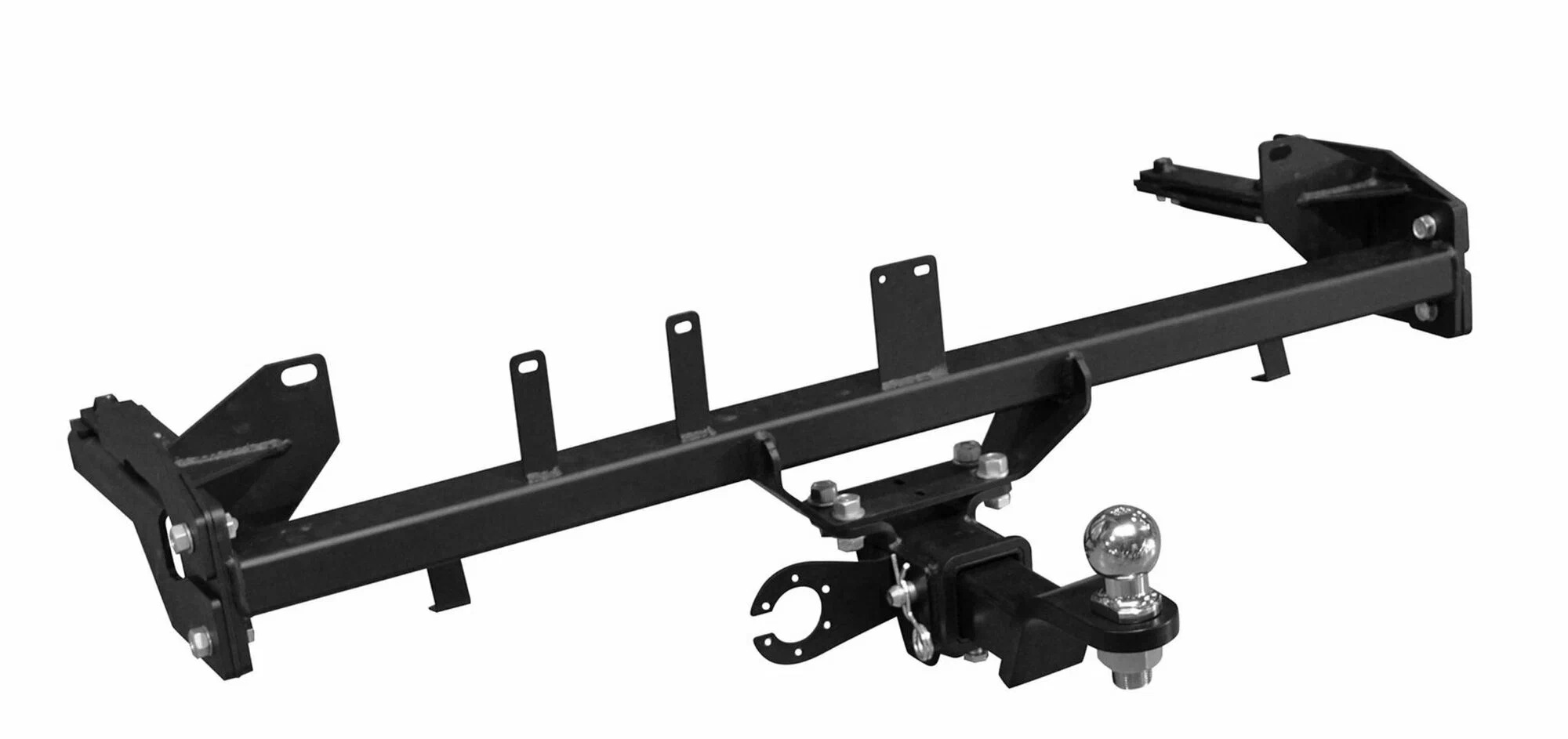

When it comes to towing, your setup is only as strong as its weakest point—and too often, that point is the towbar. Many drivers assume all towbars are built the same. They’re not.

At Kebar Manufacturing, based in Loganholme, QLD, we’ve spent decades perfecting the art of towbar fabrication. Through experience, we’ve seen first-hand how differences in design, materials, and manufacturing standards can make or break your towing experience—literally.

1. Material Matters: Not All Steel Is Created Equal

Cheap or mass-produced towbars often use low-grade steel or thinner tubing to cut costs. While that may reduce the price tag, it also compromises strength and longevity—especially under Australian road conditions.

At Kebar Manufacturing, we use high-tensile Australian-grade steel, precision-cut and welded in-house. It’s the only way to ensure the bar can handle the stress of regular towing, off-road movement, and long-distance travel.

2. One-Size-Fits-All? Not Here.

Generic or imported towbars may be labelled “universal,” but they rarely offer a true fit. Misalignment or poor fitting can result in:

- Strain on the chassis

- Reduced towing capacity

- Increased risk of detachment or failure

At our Loganholme workshop, every towbar is custom-built to suit your specific make and model. Whether you drive a ute, SUV, motorhome, or 4WD, we tailor the design to ensure it mounts cleanly, safely, and in compliance with ADR 62 standards.

3. Compliance Isn’t Optional—It’s the Law

In Australia, towbars must meet the Australian Design Rules (ADR) for safety and performance. Unfortunately, not all aftermarket bars meet these requirements—especially imported products.

Kebar Manufacturing is an ADR-compliant facility. Every towbar we install meets or exceeds the national safety standards. For motorhome owners and A-frame towing, our Pro-Tow Predator system is Australia’s first fully certified A-frame towing system, tested for over two million cycles.

4. Welding That Withstands the Road

A towbar is only as strong as its welds. At Kebar, our tradespeople don’t cut corners. We use:

- Precision MIG and TIG welding

- Full-penetration welds where strength is critical

- In-house quality control before anything leaves our workshop

Every bar we make is structurally tested, road-ready, and built to last.

5. You’re Not Just Buying a Product—You’re Backed by Experts

We’re not just fabricators. We’re problem-solvers. Our team in Loganholme includes engineers, licensed auto electricians, and skilled installers who will:

- Help you choose the right towbar setup

- Fit it expertly to your vehicle

- Provide ongoing advice on towing safely and legally

Whether you’re towing for work, hauling a trailer, or heading off on a caravan trip, our goal is to make towing safe, smooth, and stress-free.

Why Choose Kebar Manufacturing in Loganholme?

- 🔩 Custom Design & Fabrication

- ✅ ADR-Compliant & Engineer Certified

- 🔧 In-House Installation Team

- 🏆 40+ Years of Towing Expertise

We’re proud to serve customers across Queensland and beyond, offering towbars and towing solutions that are built strong, fit right, and hold up to whatever the road throws your way.

Ready to Upgrade?

Trust Kebar Manufacturing for custom-built, ADR-compliant towbars that deliver strength, safety, and peace of mind. Whether you’re towing for work, travel, or adventure—we’re here to help you move forward with confidence.

Visit us at 10 Chetwynd St, Loganholme QLD, or give us a call at (07) 3209 7669.